בתור זוכה של פרסי איכות מושל שנדונג (אישי), אחת מאולמות המותג הראשונות של "מוצרים טובים משנדונג", וכן יזם של "ייצור שנדונג - מוצרים מצוינים של צ'ילו" ו"ייצור שנדונג - מוצרים מובחרים של לואו צ'יין", החברה רוד שיפרה באופן מתמיד את מערכת הניהול באיכות, יישמה במרץ פיתוח המובלט על ידי תקנים, וביצעה פריצות דרך מתמשכות בטכנולוגיות מפתח, וצברה בהדרגה מעמד של יזם מוביל בתעשיית החומרים החדשים. 제품יה משמשים בהצלחה רבה באלפי פרוייקטים מרכזיים של המדינה ובפרויקטי תשתיות גדולים. החברה אושרה כיזם דוגמה של יצרן מוביל ברמה הארצית, יזם דוגמה לרמת נכסים רעיוניים ברמה הארצית, יוזמת ניסיון לאomens תקן לייצור חכם ברמה הארצית, וכאחת מהמתקהלות הראשונות של מעבדות סטנדרטים איכותיים של מחוז שנדונג. לאחד מעובדיה הוענק הכינוי "מנהל איכות ראשי דוגמה של מחוז שנדונג".

גיאוסינטטים הם חומרים יסודיים מרכזיים לפרויקטים לאומיים גדולים בתשתיות תחבורה, שמירת מים, אנרגיה וביטחון לאומי. הביצועים שלהם משפיעים ישירות על ביטחון הנדסי, אורך חיים ושילוב יעד ה"פחמן הכפול". החברה מחויבת לבנות מודל אינטליגנטי לניהול איכות שמכסה את מחזור החיים של המוצר כולו, ולשדרוג האיחוד העמוק של ייצור, פיתוח וניהול עם טכנולוגיות מתקדמות כגון אינטרנט של הדברים, נתונים גדולים ובינה מלאכותית. מדדי איכות עיקריים משיגים איסוף נתונים, ניתוח ודיווח מלא לאורך התהליך. החברה פיתחה את קו הייצור הראשון בעולם לג membrנה גיאוטכנית HDPE ברוחב 12 מטר, עברה טכנולוגיות ליבה כמו בקרת בועות ממברנה וניטור מקוון, והשלימה מערכות אינטליגנטיות כגון זיהוי ניצוץ חשמלי ומדידת עובי בקרני X, ופתרה בהצלחה את בעיות הכאב התעשייתיות של membrנות גיאוטכניות מסורתיות, כלומר "רבות תפרים וכفاءה נמוכה". החברה קיבלה אישור להקים אחד מהמפעלי המובילים במחוז שנדונג בתחום מעבדת התקנים ואיכות גיאוסינטטים, enfוקסת על פתרון בעיות איכות נפוצות בתעשייה ולחזק את היכולת התחרותית הבינלאומית של תעשיית הגיאוסינטטים של שנדונג.

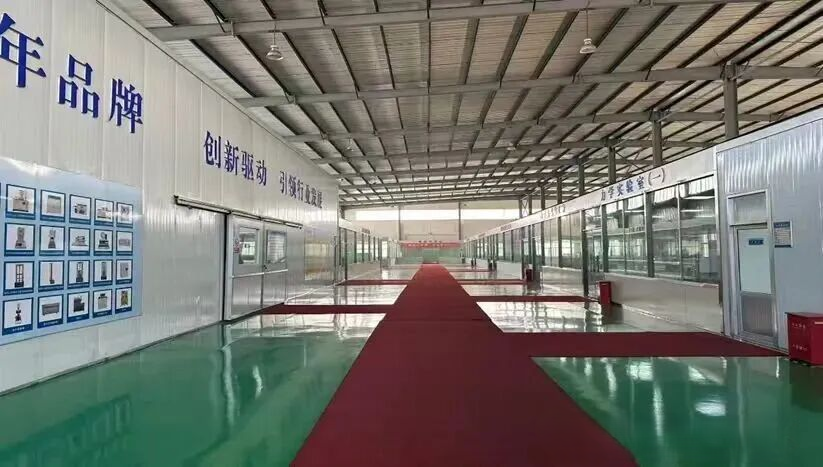

החברה הגדילה באופן מתמיד את ההשקעות שלה במדעים ובטכנולוגיה, והקימה מרכז לעיצוב תעשייתי ברמה לאומית, תחנת מחקר פוסט-דוקטורטית ברמה לאומית, ו-10 פלטפורמות מחקר ברמה פרובינציאלית ומשרדיות. תוך התמקדות בפריצות טכנולוגיות מתקדמות, נוצרו חמישה מעבדות متخصصות, כולל מעבדות למכניקה ולמדע הפולימרים, אשר יצרו לולאה סגורה של «מחקר ופיתוח–ייצור ניסיוני–ייצור המוני», עם קו ייצור ניסיוני אוטומטי לחלוטין. החברה נבחרה כפרויקט מפתח באסכולת פטנטים תעשייתית בפרובינציית שנדונג, ובכך השיגה ניהול מרכזי, יישום שיתופי והמרות יעילות לטכנולוגיות פטנטיות. מרכז חדשנות הסטנדרטים לטכנולוגיות חומרים חדשים גיאוסינתטיים בפרובינציית שנדונג הושלם בהצלחה, ובהובלת כתיבת או השתתפות בכתיבת (או בעדכון) של יותר מ-60 תקנים לאומיים ותעשייתיים. החברה זכתה ביותר מ-30 פרסי מדעים וטכנולוגיה ברמה לאומית ופרובינציאלית, לרבות פרס הפטנטים של סין על מצוינות ופרס הראשון לתקדמות המדעים והטכנולוגיות בפרובינציית שנדונג, מה שמרחיב את עמידות שרשרת האספקה התעשייתית ואת היכולת התחרותית הכוללת. החברה הצליחה לפתח בצלחת לא ארוגה מסיבי פוליפרופילן במערכת ספונבונד עם דיקור, אשר מאפיינה ביצועים גבוהים, ושהשיגה שיפור משמעותי במדדי הביצוע המרכזיים: עוצמת המשיכה עלתה ביותר מ-30%, עמידות לתיקון עלתה ב-18%, ועוצמת הקירור לאורך ולרוחב עלתה ביותר מ-10%.

בהתבסס על מטרות ה"פחמן הכפול", החברה מעצבת מחדש את האkosיסטמה התעשייתית באמצעות ייצור ירוק. בעזרת מערכות ייצור ירוקות חכמות, טכנולוגיות לחיסכון באנרגיה וצמצום פליטות ויישומי מוצרים בעלי ביצועים גבוהים, בנתה מערכת סלילת שרשראות אספקה ירוקה מלאה. המוצרים המרכזיים שלה נבחרו לאחת ממקרי היישום הראשונים של הטכנולוגיות הלאומיות לחיסכון באנרגיה ונכללו בקטלוג השידור של משרד האקולוגיה והסביבה לטכנולוגיות נמוכות פחמן. החברה הגיעה לצמצום של 30% בצריכת אנרגיה כללית ל-10,000 יואן של ערך תפוקה וצמצום של 27.6% בצריכת אנרגיה כללית ל-10,000 יואן של ערך מוסף. הפכה להיות המפעל הירוק הלאומי הראשון בתעשייה וזכתה להכרה כמפעל דוגמה לאומי לעיצוב ירוק של מוצרים תעשייתיים. מודל הפיתוח הירוק של החברה יצר אפקט שידור ניתן לשכיחות ולבניית קנה מידה, ודוחף באופן מתמיד את תעשיית הסינטטיות הגיאולוגיות לקראת פיתוח חכם, ירוק, איכותי ובר-קיימא.