Even though it is a heavy duty material, the poor installation may cause problems even in this final product. Poor seam connections are common with the overlapping and securing of fabric not in its best shape. These can become weak spots in the geotextile, causing it to rip and rupture when pressured. This problem can be thwarted by using the manufacturer’s recommendations for seaming and keeping the fabric taut during installation

Also common is a problem with the installation of woven geotextile as well as site preparation. It can cause the soil to settle unevenly and not drain well if the soil is not compacted or graded properly prior planting the fabric. This can be prevented by making sure the site is well prepared before the geotextile is put down, that it's properly levelled and compacted so as to provide a stable base for the fabric.

Correct installation of woven geotextile is critical for its performance and life expectancy in landscaping and civil engineering applications. When contractors and engineers follow the manufacturer’s recommendations while paying attention to site preparation, they can articulate common problems and gain peace of mind that their projects will stand the test of time

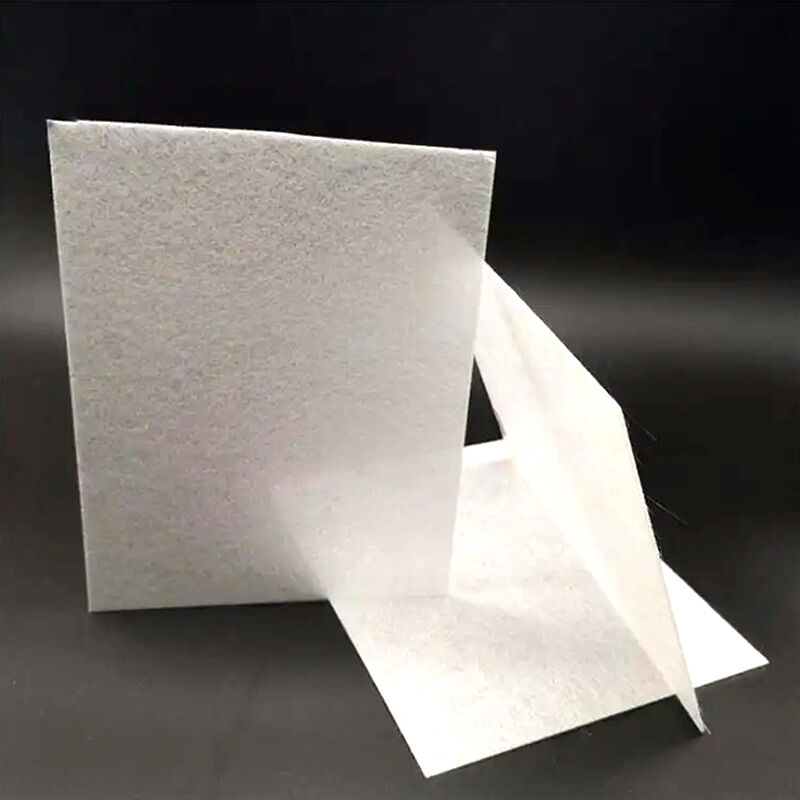

Woven geotextiles are fabric like material manufactured by weaving synthetic fibers, such as polyester or polypropylene. These materials are intended for usage in applications where high strength, ruggedness, and resistance to environmental agents such as sunlight, chemicals or water are desired. Advantages of woven geotextiles in road construction. When used as a part of a pavement, dirt road or highway/freeway system, woven and non woven geotextile provide many advantages.

One of the major benefits of woven geotextile in road building is its capacity to reinforce the soil. The fabric drains early, draws moisture away from the surface and maintains stability even as it reduces road base thickness, owing to a layer of woven geotextile between subgrade and road base that spreads traffic-induced loads more uniformly on the surface. This keeps ruts, cracks and other types of damage to a minimum.

There is yet another advantage of using woven geotextile in road building and that is for erosion control. Our geo fabric material make sure that soil remains stable and doesn't get washed away due to rain water or any other kind of water runoff. This is particularly relevant for loose or erosive soil types, as it ensures roads are structurally fit-for-purpose and reduces expensive road damage maintenance.

Woven geotextiles are the top pick for erosion control project as it is tried and tested through years! Woven geotextile is a durable material. Once installed, these ground covers are very hard-wearing. Unlike other methods of erosion control such as riprap or concrete, woven geotextile is made to hold up in sun, water or chemical exposure without degrading over time.